- Needle Valve Product Catalog

|

- Needle valves are specialized valves used for metering fluid flow. Their use is primarily limited to small systems such as instrumentation or fuel regulation where the ability to control the flow of fluid precisely and repeat ably is highly desirable. Needle valves are available in two main body configurations.

- Valve design

Needle valves assemblies consist of three major portions, the valve body and seat, the stem and stem tip, and the packing and bonnet. In many instances, needle valves are small enough that their bodies can be machined directly from hex or square bar stock. Typical configurations include Z- and L-shaped flow paths through the body, sometimes referred to as globe and angle patterns, respectively.

The stem usually incorporates fine threads to allow for micrometer-like adjustment of the needle relative to the seat. Often a locking means is provided either internally, or via a set screw, locknut, etc. on the stem, in order to keep vibration from changing valve settings. Sometimes a scale is included to permit accurate resetting of the flow rate. Manufacturers will often publish curves showing the mostly linear relationship between turns of the stem and the flow coefficient, Cv.

The stem tip itself can be relatively long and tapered or somewhat short and blunt, depending on the intended application. Usually, the seat is tapered to match the taper of the needle. Tapered stem tips are employed for regulating service. Vee-point stem tips provide for leak-free shutoff in small orifice valves. Blunt vee-point stem tips are used to provide full flow with relatively few stem turns. Often a choice of stem tip material can be made as well, with metal for long life or replaceable PCTFE for lighter sealing torque. Non-rotating stem tips are used to prevent galling of the stem tip and seat.

Packing in the bonnet maintains leak-free rotation of the stem. O-rings, PTFE, or graphite materials are often used for packing. Packing pressure is adjusted through a packing or gland nut. Sometimes, two-piece stems are used to isolate the stem threads from the media and to prevent any thread lubricant from leaking into the process fluids. Sometimes the bonnet is formed as an integral portion of the valve body; in other instances, it is a separate part threaded into the body or held in place with a nut. In settings where fugitive emissions are a concern, a back seat is provided against which the stem seals when the valve is fully opened. Most designs include some method of preventing the stem from being backed completely out of the valve.

Needle valves are typically operated by hand but automatically controlled versions are available. Needle valves provide positive shut-off and can be used as Globe Valve sbut other more economical valves are available if this, and not metering, is the only requirement. Care must be taken when closing a needle valve as it is possible to damage the stem tip or the seat if torque is applied excessively.

Certain designs are available that provide rapid adjustment of flow with fewer stem turns than standard designs.

Applications

Needle valves are used in power plants, refineries, chemical plants, and in oil and gas exploration, laboratory analysis, etc. They are employed for gas chromatography, sampling, instrument air, and other uses where precise flow metering is needed.

Needle valves are typically applied as a means of reducing flow rates of liquids or gases so that they may be introduced to measuring instruments which might otherwise be damaged by the full flow. Another application is in regulating flow to air cylinders to control piston speed. They are often employed in automated combustion control systems to regulate fuel flow. Governor controlled pumps will often use needle valves as a way of cushioning the governor from damaging surges. Needle valves are sometimes used as components of larger control valves.

Material choices for valve bodies typically include stainless steel, carbon steel, nickel-copper alloys, and brass. In selecting needle valves, specialists need to consider system pressure, operating temperature, required flow rate, and materials of construction. Special designs are available for dealing with high pressures, high temperatures, corrosive fluids, etc. Some valves may be ordered with different orifice diameters to accommodate higher flow rates. Needle valves are often mounted in control panels and manufacturers usually will supply components with their valves to make these arrangements possible.

Port connections are typically offered as NPT thread, compression fitting, or socket weld options. In certain critical operations, manufacturers can provide valves that are certified for oxygen service or helium leak tested, for example.

Valve handles are offered in a variety of styles and materials, including aluminum crosses and ABS wheels, as well as in an array of colors to provide both tactile and visual cues to guide valve operation.

|

| High Pressure Needle Valve |

|

|

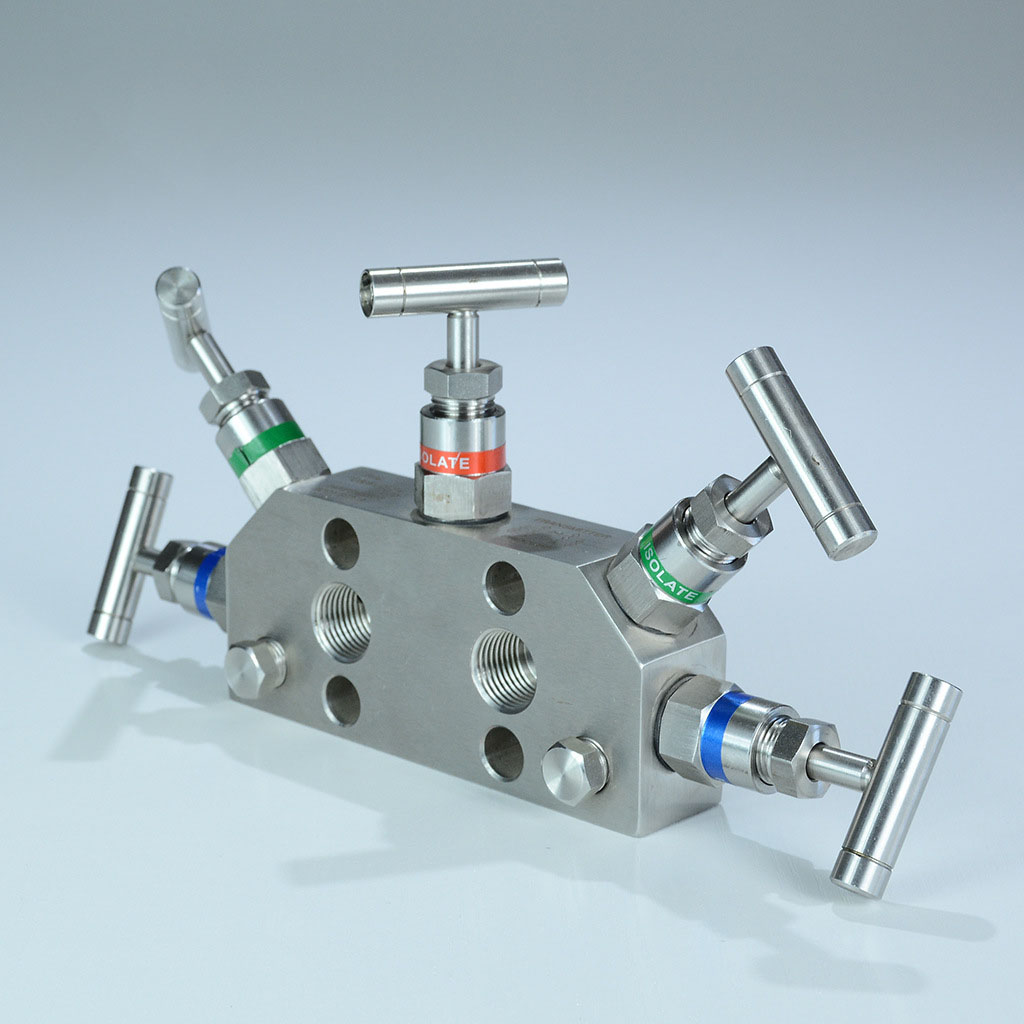

| Manifolds |

|

|

|

Needle Globe Valve |

|

|

|

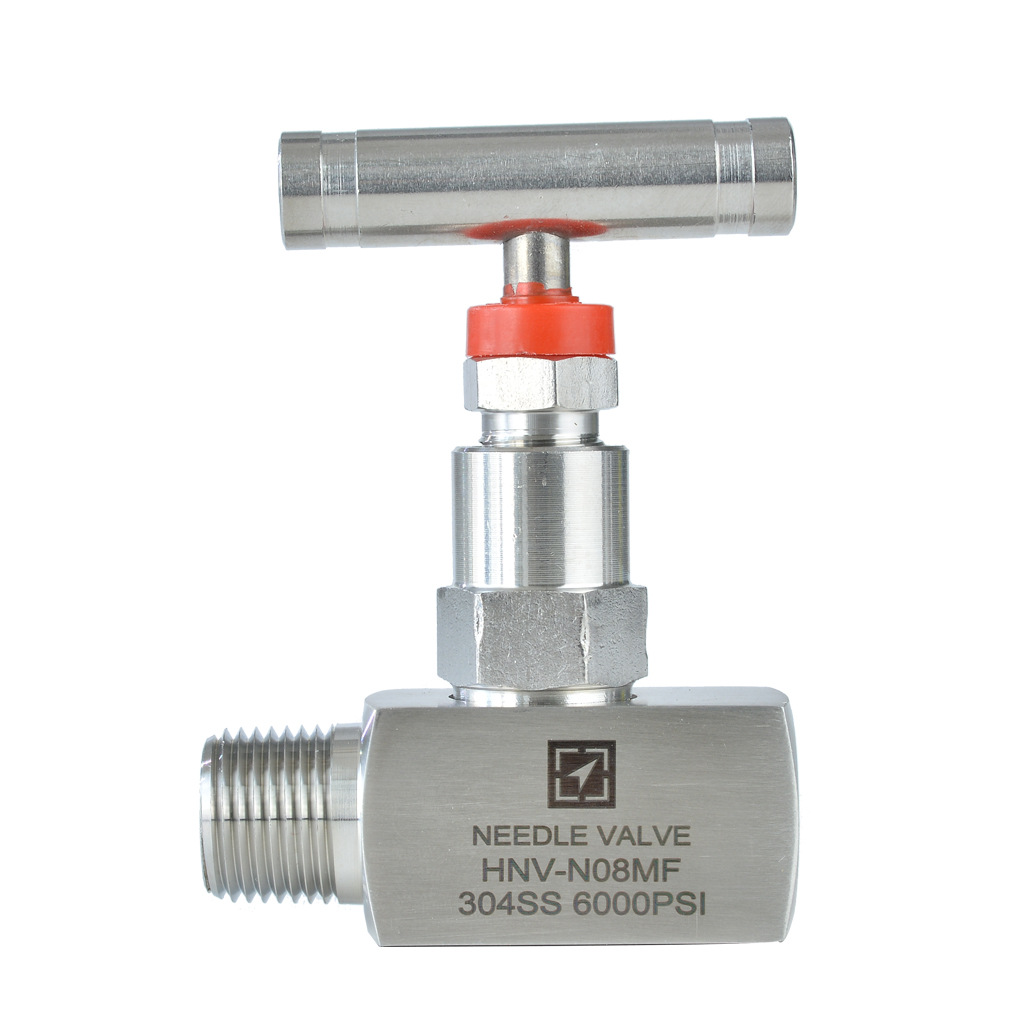

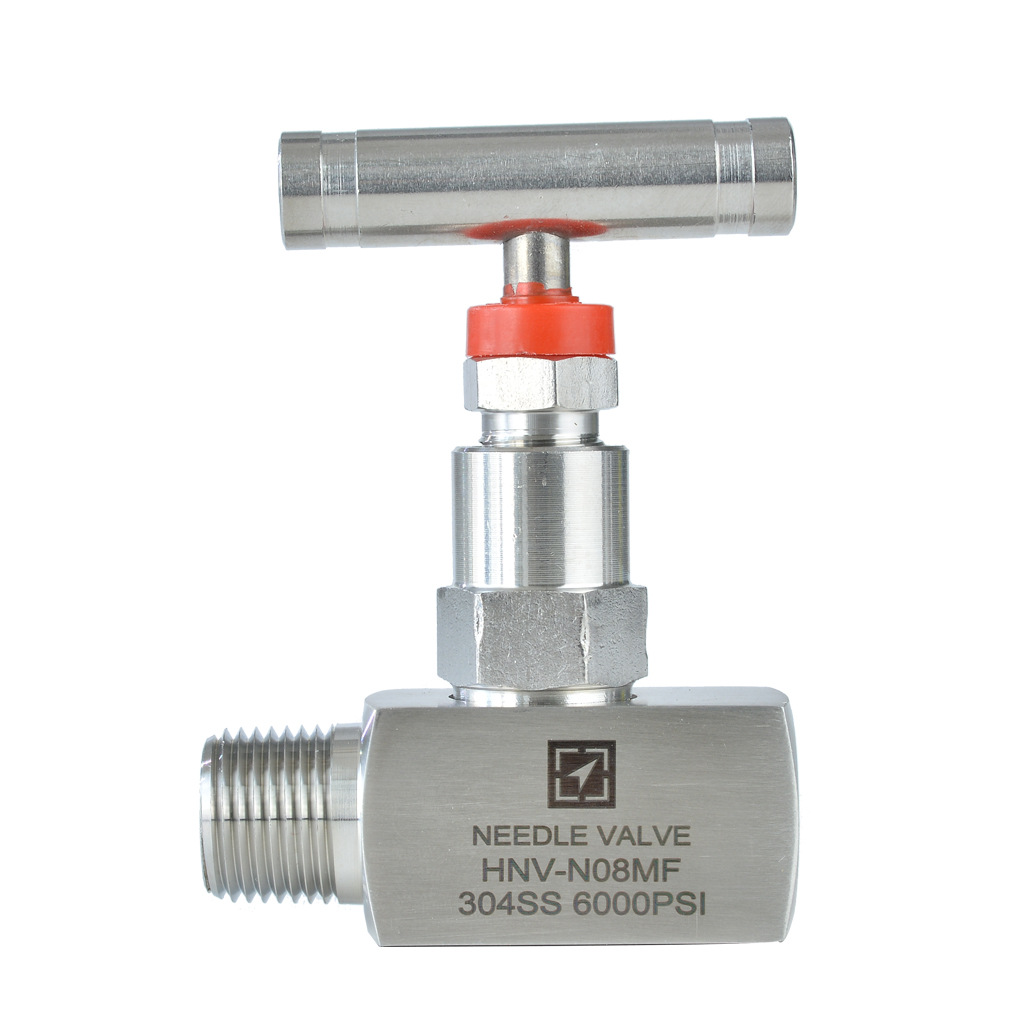

| HNV |

HNV |

HNV-N08MF |

|

|

|

| J13 |

J23 |

J61W |

|

|

|

| KH |

SNV |

THNV |

|

|

Needle Ball Valve |

| |

|

|

|

|

|

| BV |

BVF |

BVT |

|

|

|

| BVL-M06OD |

CV-04F |

CVSS |

|

|

|

| NV-M03OD |

NVM-04N |

NVT-M06 |

| |

|

|

|

|

|

All Copyright © Shanghai

Petro Valve Factory

Factory Add: No.318 Fulian 2 Road, Baoshan

Disctrict, Shanghai City, China

Marketing Add: No. 301-3, Lunchang Road,

Lunchang Town, Nanan City, Fujian, China

Tel: 0086 595 23225000, 0086 189 0505 9981

Email:

topval1992@163.com

|